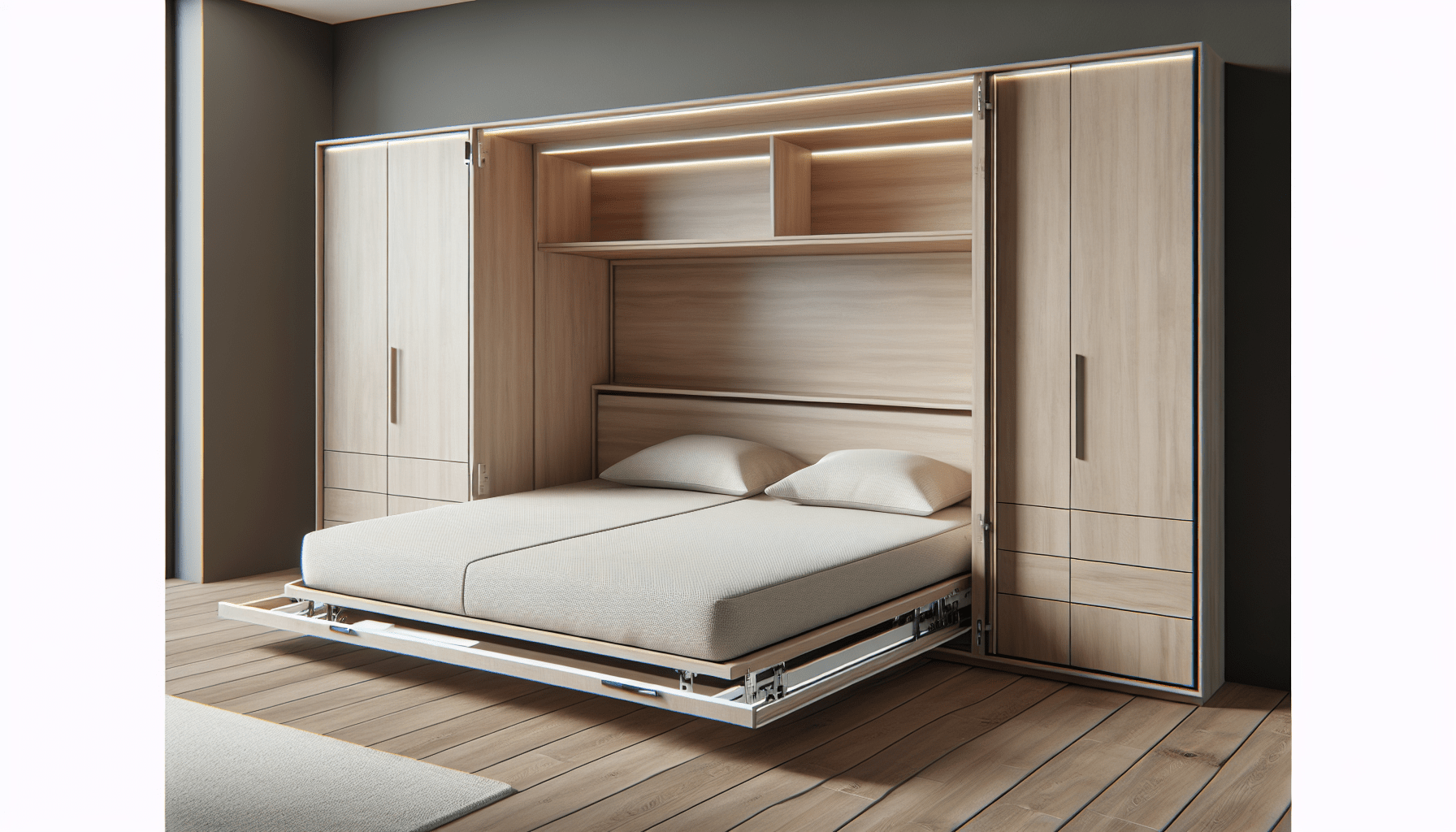

In this informative article titled “Murphy Bed with Cheap $20 Hardware,” DIYTyler provides a step-by-step video tutorial on building a wooden Murphy wall bed using affordable $20 hardware. By opting to construct your own Murphy bed, you can save a significant amount of money compared to purchasing a kit for almost $300. The bed is made from 3/4″ red oak PureBond plywood, and the design is similar to other Murphy bed designs. Along with the detailed instructions, the article also mentions the materials needed, such as five sheets of plywood, and the additional shelves that can be made using different sheet sizes. From ripping plywood sheets to attaching swivel brackets and finishing touches, this article covers all the key steps involved in building your own Murphy bed with floating shelves as legs.

Overview of Murphy Bed with Cheap $20 Hardware

Introduction to DIYTyler’s tutorial

In DIYTyler’s tutorial, he demonstrates how to build a wooden Murphy wall bed using inexpensive $20 hardware. This project offers significant cost-saving benefits compared to buying a pre-made Murphy bed kit for nearly $300. The design of the bed is made from 3/4″ red oak PureBond plywood and is similar to other Murphy bed designs. By following DIYTyler’s tutorial, you can build a high-quality Murphy bed at a fraction of the cost.

Cost-saving benefits of building your own Murphy bed

Building your own Murphy bed provides numerous cost-saving benefits. Instead of purchasing a pre-made kit for nearly $300, you can build your own bed for a fraction of the cost. By using affordable $20 hardware, such as simple boat seat swivel bearings, you can achieve the same functionality as an expensive pre-made kit. Additionally, DIY projects often allow you to customize the design and materials used, giving you the ability to create a bed that fits your specific needs and style preferences.

The use of simple boat seat swivel bearings as hardware

One of the key cost-saving features of this Murphy bed tutorial is the use of simple boat seat swivel bearings as hardware. These inexpensive swivel bearings provide smooth and reliable motion for the Murphy bed, allowing it to be easily raised and lowered. By using this affordable alternative to traditional Murphy bed hardware, you can achieve the same functionality without breaking the bank.

Building the bed with 3/4″ red oak PureBond plywood

To build the Murphy bed, DIYTyler recommends using 3/4″ red oak PureBond plywood. This type of plywood is durable, high-quality, and aesthetically pleasing. PureBond plywood is also manufactured in North America and is formaldehyde-free, making it a healthier option for your DIY project. By using this specific type of plywood, you can ensure that your Murphy bed is sturdy and built to last.

Similarities to other Murphy bed designs

While DIYTyler’s Murphy bed design is unique, it shares similarities with other Murphy bed designs. The overall concept of a wall bed that folds up into the wall to save space is common among all Murphy bed designs. By following DIYTyler’s tutorial, you can create a Murphy bed that is similar in functionality to other designs, but with the added benefit of cost savings.

Materials and Tools Required

To build the Murphy bed with cheap $20 hardware, you will need the following materials and tools:

- 5 sheets of 3/4″ red oak PureBond plywood: This high-quality plywood will serve as the main material for constructing the bed frame.

- Additional plywood for shelves: QTY 3 3/4″ sheets and QTY 2 1/4″ sheets of plywood will be needed to construct the floating shelves on either side of the bed.

- Edge banding: A large roll of edge banding will be used to finish the edges of the plywood, creating a polished and professional appearance.

- Kreg Jig: The Kreg Jig is a key tool for creating secure joinery in the bed frame.

- Wood glue: Wood glue is essential for bonding the various pieces of plywood together.

- Pocket hole screws: These screws are used in conjunction with the Kreg Jig to create secure and hidden joinery.

- Brackets for floating shelves: Brackets will be used to attach the floating shelves to the bed frame.

- Solid oak for edge banding: Solid oak strips will be used to edge band the bed frame, providing added durability and protection.

- Swivel brackets for bed motion: The inexpensive boat seat swivel bearings will serve as the hardware for the bed’s motion.

Step-by-Step Instructions

Follow these step-by-step instructions to build your own Murphy bed with cheap $20 hardware:

Ripping and cutting the plywood sheets

Start by using a table saw to rip and cut the 3/4″ red oak PureBond plywood sheets into the necessary sizes and lengths for the bed frame and shelves. This will ensure that all the pieces fit together properly during assembly.

Using edge banding to finish the edges

After cutting the plywood sheets, use edge banding to finish the edges of the plywood. Applying edge banding creates a polished and professional appearance for the bed frame and shelves.

Utilizing the Kreg Jig for secure joinery

To create secure joinery in the bed frame, use a Kreg Jig to drill pocket holes in the appropriate locations. The Kreg Jig allows for hidden joinery, ensuring a clean and seamless look for the finished bed.

Assembling the bed frame and attaching the headboard

Using wood glue and pocket hole screws, assemble the bed frame according to DIYTyler’s instructions. Make sure to attach the headboard securely to the bed frame to ensure stability and durability.

Creating the floating shelves with brackets and plywood

Construct the floating shelves using brackets and plywood. Measure and cut the plywood to the desired dimensions, then attach the brackets to the shelves. The floating shelves will serve as both storage and support for the Murphy bed when it is in the down position.

Achieving continuous grain and mitered corners for shelves

To achieve a seamless and professional look for the floating shelves, utilize continuous grain and mitered corners. By carefully aligning the plywood pieces and cutting precise miters, you can create a visually appealing and cohesive design.

Edging banding the bed frame with solid oak for durability

To add durability to the bed frame and protect the edges, apply solid oak edge banding. Cut the solid oak strips to size and attach them to the exposed edges of the plywood using wood glue and brad nails. This will ensure that the bed frame can withstand daily use without any damage.

Adding swivel brackets for smooth motion of the Murphy bed

Install the swivel brackets to allow for smooth motion of the Murphy bed. Drill holes in the appropriate locations on the bed frame and attach the swivel brackets using machine screws. Ensure that the brackets are properly aligned and secured for safe and reliable operation of the Murphy bed.

Attaching shelves to the bed frame

Once the bed frame and floating shelves are complete, attach the shelves to the bed frame using screws. This will provide additional support for the bed when it is in the down position and add functionality to the overall design.

Securing all parts with screws and glue

Throughout the assembly process, be sure to secure all parts with a combination of screws and wood glue. This will ensure that the bed frame and shelves are stable and long-lasting.

Finishing Touches

After the bed is fully assembled, it’s time to apply the finishing touches for a professional and polished appearance.

Sanding the bed for a smooth finish

Start by sanding the entire bed using 180-grit sandpaper. This will smooth out any rough edges or imperfections, leaving you with a clean and seamless surface.

Applying a tinted high-performance topcoat

To enhance the appearance and protect the wood, apply a tinted high-performance topcoat. Mix a small amount of water-based stain with the topcoat to achieve your desired color. Use a HVLP spray system for an even and smooth application. Allow the topcoat to dry fully before proceeding.

Ensuring a professional and polished appearance

Inspect the bed for any remaining imperfections or rough areas. Sand away any flaws and touch up the finish as needed. This will ensure that the bed has a professional and polished appearance when it is completed.

Setting Up the Murphy Bed

Once the bed is fully finished, it’s time to set it up in your chosen location.

Fastening the bed frame to the wall

To secure the Murphy bed frame to the wall, follow the instructions provided in DIYTyler’s tutorial. Use appropriate wall anchors, screws, or other methods to ensure that the bed is securely fastened and safe to use.

Adding the mattress for comfort

With the bed frame securely fastened to the wall, add a mattress of your choice for comfort. Choose a mattress that fits the bed frame properly and provides the desired level of support for a good night’s sleep.

Conclusion

Building a Murphy bed with cheap $20 hardware offers numerous benefits and cost savings. By following DIYTyler’s tutorial, you can create a high-quality and functional Murphy bed at a fraction of the cost of buying a pre-made kit. The use of 3/4″ red oak PureBond plywood and simple boat seat swivel bearings provides durability and smooth motion. By incorporating floating shelves into the design, you can further enhance the functionality of the Murphy bed. With proper assembly and finishing touches, you can achieve a polished and professional result that will save you space and money while providing a comfortable sleeping solution.